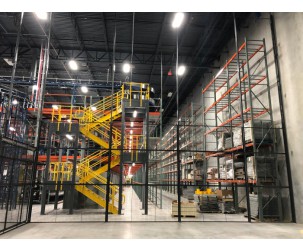

Pallet racking inspections are crucial for maintaining safety and efficiency in warehouses and storage facilities. These inspections are typically carried out to ensure pallet racks are in good condition, stable, and safe to use.

Here are the key aspects of pallet racking inspections:

♦ Frequency of Inspections: Regular inspections are necessary. The frequency can vary based on the usage intensity, the age of the racks, and environmental factors. Some facilities conduct inspections annually, while others might do it more frequently.

♦ Professional Inspectors: These inspections are often carried out by trained professionals with expertise in warehouse safety and pallet racking systems. They can identify potential issues that may not be obvious to untrained staff.

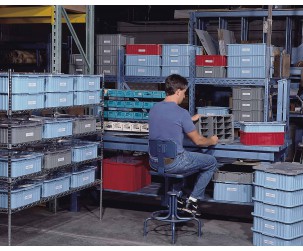

♦ Inspection Checklist: The inspection typically includes checking for:

° Damage to uprights, beams, braces, and welds.

° Proper alignment and plumpness of racks.

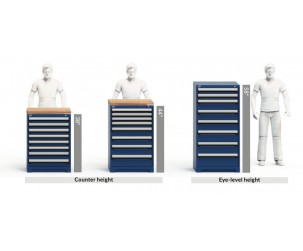

° Load capacity signs and ensuring loads don’t exceed these limits.

° The condition of floor anchors and their proper installation.

° Signs of corrosion or material fatigue.

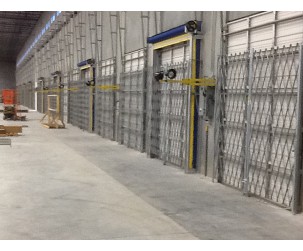

° Proper aisle space and clearances.

♦ Reporting and Documentation: A detailed report is usually provided after the inspection. This report includes any findings and recommendations for repairs or replacements if needed.

♦ Follow-Up Actions: If issues are identified, prompt action is required to address them. This may involve repairing or replacing damaged components, adjusting loads, or making other changes to ensure safety.

♦ Training for Staff: Apart from professional inspections, it's also crucial for warehouse staff to be trained in identifying potential issues with pallet racking systems. This can help in early detection of problems.

♦ Compliance with Regulations: Workplace health and safety regulations often mandate pallet racking inspections. Compliance with these standards is a legal requirement and a crucial aspect of maintaining a safe working environment.

Regularly inspecting and maintaining pallet racking systems are vital to preventing accidents and ensuring a safe and efficient storage environment.

Note: Always follow the manufacturer's instructions and safety guidelines when using this product. Following the manufacturer's guidelines is generally a good idea when using any product or equipment. Still, it's also essential to use your judgment and seek expert advice when necessary. Specifications are subject to change without notice.