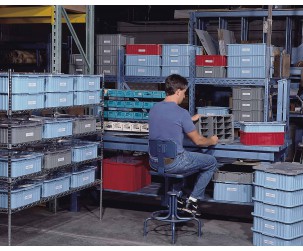

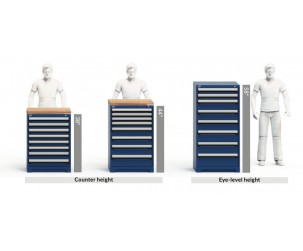

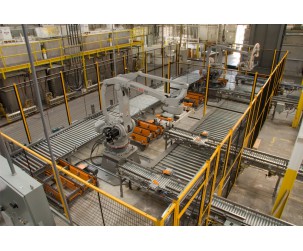

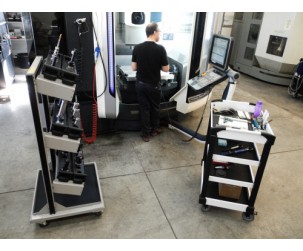

MFG Tray Conveyor and Assembly Trays feature a low-profile design and radial edges to readily accommodate conveyor transport and assembly operations in various applications. Four distinct corner profiles are available to integrate with rack systems and conveyors or for nesting or stacking capabilities. Their dimensional stability and light weight ensure easy transporting and handling.

Composite construction enables these trays to be constantly used in temperatures ranging from -60° to 250° F (-51° to 121° C) and intermittently in temperatures up to 300° F. They resist cutting oils, greases, radiation, mild acids, and alkaline solutions with a pH rating of 3.0 – 10.0. And, unlike many thermoplastic units, they will not melt when in contact with most hot objects.

Benefits:

♦ Durability and Strength: Fiberglass is known for its strength and resistance to wear, ensuring that the trays can handle heavy loads without deformation.

♦ Corrosion Resistance: Fiberglass is resistant to many chemicals, which means these trays can be used in environments where they might come into contact with corrosive substances without damage.

♦ Temperature Resistance: Fiberglass trays can withstand a wide range of temperatures, making them suitable for both high and low-temperature applications.

♦ Lightweight: Despite their strength, fiberglass trays are relatively lightweight, which can help reduce energy consumption in conveyor systems and ease handling.

♦ Low Maintenance: Fiberglass does not rust, corrode, or rot, which results in low maintenance costs and longer service life.

♦ Cost-Effective: When considering their lifespan and reduced maintenance, fiberglass trays can be more cost-effective in the long run compared to other materials.

♦ Customizability: Fiberglass can be molded into various shapes and sizes, allowing manufacturers to produce trays tailored to specific needs.

♦ Smooth Surface: The smooth surface of fiberglass trays ensures easy cleaning and prevents products from sticking, which is crucial in food processing or pharmaceutical industries.

Uses:

♦ Electronics Manufacturing: Given their non-conductive nature, fiberglass trays are perfect for assembling and transporting electronic components.

♦ Food Processing: The chemical and temperature resistance of fiberglass makes it ideal for trays used in food processing, especially where trays need to be cleaned regularly.

♦ Pharmaceuticals: The easy-to-clean nature of fiberglass and its chemical resistance makes it a good choice for pharmaceutical applications.

♦ Automotive Industry: Fiberglass trays can be used in the assembly lines of automotive parts, especially in applications where chemical resistance is required.

♦ Aerospace: In manufacturing aerospace components, fiberglass trays can be used for parts assembly and transportation due to their strength and lightweight properties.

♦ Chemical Processing: These trays can withstand exposure to various chemicals, making them ideal for chemical processing plants.

♦ Material Handling: In various industries, fiberglass trays can be used for general material handling, including sorting, storage, and transportation.

In summary, fiberglass conveyors and assembly trays offer a combination of durability, resistance to various environmental factors, and adaptability, making them suitable for various industries and applications.

Note: Always follow the manufacturer's instructions and safety guidelines when using this product. Following the manufacturer's guidelines is generally a good idea when using any product or equipment. Still, it's also essential to use your judgment and seek expert advice when necessary. Specifications are subject to change without notice.