Benefits and Uses of All-Welded Steel Stock Trucks for material handling and storage in various industries.

Here are some key advantages:

♦ Durability and Strength: Steel is a highly durable material, and all-welded construction ensures that these trucks have superior strength. This makes them ideal for handling heavy loads and use in demanding industrial environments.

♦ Longevity: The all-welded design means there are no bolts or screws that can loosen over time. This contributes to a longer lifespan of the truck, as it's less likely to require repairs or replacement parts.

♦ Low Maintenance: All-welded steel trucks typically require less maintenance than other material handling equipment types. The absence of joints and fasteners that need tightening or replacing over time reduces maintenance needs.

♦ Enhanced Safety: The sturdy construction reduces the risk of collapse or damage under heavy loads, ensuring safer operations for workers.

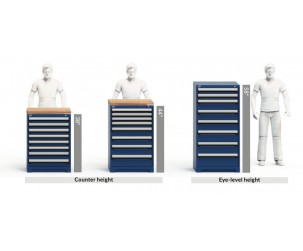

♦ Versatility: These trucks can be designed in various sizes and configurations, making them suitable for various applications, from warehouses and factories to retail and healthcare settings.

♦ Better Load Handling: The rigid structure provides better stability and control when moving heavy or bulky items, reducing the risk of accidents or damage to the goods.

♦ Resistance to Corrosion and Damage: Steel, especially when treated or coated, is resistant to corrosion, rust, and other environmental damage, making these trucks suitable for use in various conditions, including outdoor settings.

♦ Improved Maneuverability: Many all-welded steel stock trucks come with high-quality casters and wheels that enhance maneuverability, making it easier to navigate through tight spaces.

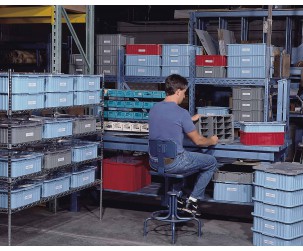

♦ Customizability: They can often be customized with various features like shelves, drawers, or hooks to suit specific needs and improve efficiency in material handling.

♦ Eco-Friendly: Steel is recyclable, making these trucks a more sustainable option than some less easily recyclable materials.

All-welded steel stock trucks are versatile and robust tools in various industries and settings.

Here are some of their primary uses:

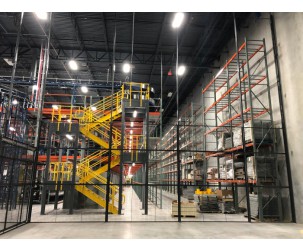

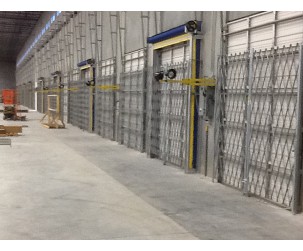

♦ Material Handling in Warehouses: These trucks are ideal for transporting goods within warehouses. They can easily maneuver through aisles and carry heavy loads, making them essential for stock management.

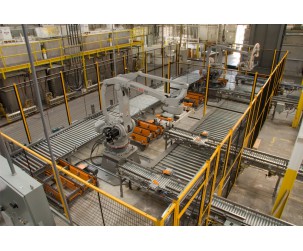

♦ Industrial Applications: In manufacturing plants and other industrial settings, all-welded steel stock trucks transport raw materials, components, and finished products from one part of the facility to another.

♦ Retail and Supermarkets: These trucks are commonly used in retail environments, including supermarkets and department stores, for moving stock from storage areas to shelves.

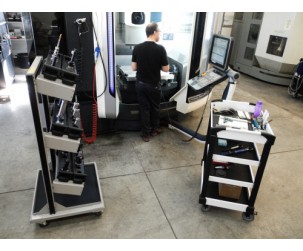

♦ Tool Transportation in Workshops: In workshops and garages, they are handy for moving tools and equipment around the work area.

♦ Hospitality and Catering: In hotels and large catering events, these trucks transport food, beverages, and tableware efficiently.

♦ Hospitals and Healthcare Facilities: They transport medical supplies, equipment, and sometimes even linens and laundry.

♦ Educational Institutions: In schools and universities, they assist in moving books, laboratory equipment, and other educational materials.

♦ Construction Sites: They move building materials, tools, and equipment around construction sites.

♦ Agricultural Settings: In farms and greenhouses, these trucks can transport produce, feed, and farming equipment.

♦ Maintenance and Janitorial Work: For moving cleaning supplies, tools, and waste materials, these trucks are efficient and durable.

The all-welded construction of these trucks provides durability and longevity, making them a reliable choice in environments where they might be subject to rough handling or heavy loads. Their design usually includes features like robust wheels for easy maneuvering and flatbeds or shelving for organized transport of goods.

.jpg)