A Rousseau CNC tool cart offers several benefits in a workshop or manufacturing environment. Rousseau is a well-known manufacturer of high-quality tool storage and organization equipment.

Here are some of the benefits you can expect from a Rousseau CNC tool cart:

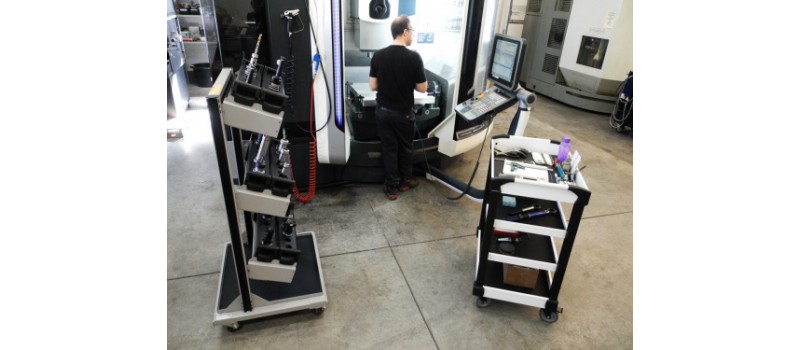

♦ Improved Organization: CNC tool carts are designed to provide a dedicated and organized space for CNC (Computer Numerical Control) tools and accessories. This helps to reduce clutter and make it easier to find the right tool when needed, ultimately saving time and increasing efficiency.

♦ Mobility: Most Rousseau CNC tool carts come with wheels or casters, making them easy to move around the workshop. This mobility allows you to bring your tools closer to the work area, reducing the need to walk back and forth to retrieve tools.

♦ Tool Protection: These carts typically have drawers or compartments with foam inserts or custom fittings that securely hold and protect your CNC tools. This minimizes the risk of damage and prolongs the lifespan of your tools.

♦ Security: Rousseau CNC tool carts often come with locking mechanisms to keep your tools safe and secure. This is especially important in shared workshop environments or to prevent theft.

♦ Space Savings: Tool carts are designed to be compact and space-efficient. They can fit into tight spaces in your workshop while providing ample storage for your tools.

♦ Customization: Many Rousseau tool carts can be customized to meet your needs. You can choose the number and size of drawers, the layout of compartments, and even add accessories like power strips or USB ports.

♦ Ergonomics: The design of these carts takes into consideration ergonomics and ease of use. This means that tools are typically stored at a comfortable height and can be accessed without excessive bending or reaching.

♦ Durability: Rousseau is known for manufacturing high-quality and durable storage solutions. CNC tool carts are often made from robust materials that can withstand the demands of an industrial or workshop setting.

♦ Productivity Boost: With tools organized and easily accessible, workers can complete tasks more efficiently. This can lead to a boost in productivity and a reduction in downtime.

♦ Professional Appearance: CNC tool carts can help create a more organized and professional-looking workspace. This can be important for customer-facing areas or when showcasing your workshop.

♦ Safety: Proper tool storage and organization can help reduce the risk of accidents and injuries in the workplace by preventing tools from being left lying around or cluttering workspaces.

In summary, a Rousseau CNC tool cart can enhance your workshop or manufacturing environment's efficiency, safety, and organization. It provides a convenient and secure way to store and transport CNC tools, ultimately contributing to improved productivity and a more professional workspace.

Here are some typical uses of Rousseau CNC tool carts:

♦ CNC Machine Tool Storage: CNC tool carts are commonly used to store and organize tools and accessories frequently used with CNC machines. This includes end mills, drill bits, collets, tool holders, and measurement instruments. The carts can be configured with custom foam inserts or compartments to securely hold these tools, making them readily accessible to operators.

♦ Tool Maintenance and Repair: These carts can be used as mobile workstations for maintenance and repair. They provide a convenient workspace for technicians to inspect, clean, sharpen, or perform routine maintenance without returning to a dedicated tool room.

♦ Assembly and Inspection: Rousseau CNC tool carts can be utilized as mobile assembly stations. Workers can use the cart's surface to assemble components, inspect parts, or perform quality control checks. The tool cart's mobility allows it to be positioned near the assembly line or inspection area.

♦ Tool Transport: One of the primary purposes of these carts is to transport CNC tools and accessories from one location to another within a workshop or manufacturing facility. The carts are equipped with wheels or casters, making it easy to move tools and equipment to the point of use.

♦ Inventory Control: Rousseau CNC tool carts can be part of an inventory control system. Designating specific tools and quantities for each cart makes tracking tool usage and inventory levels easier. This can help prevent tool shortages and improve tool management.

♦ Lean Manufacturing: In lean manufacturing environments, tool carts implement 5S principles (Sort, Set in order, Shine, Standardize, Sustain). They assist in maintaining a clean and organized workspace while ensuring that tools are readily available when needed, contributing to a more efficient and streamlined manufacturing process.

♦ Maintenance and Repair Workshops: Maintenance departments in various industries use these carts to store and transport tools and equipment needed for equipment maintenance and repair tasks. This ensures that maintenance technicians have the necessary tools, reducing downtime.

♦ Aerospace and Automotive Manufacturing: Industries such as aerospace and automotive manufacturing, where precision and efficiency are crucial, often employ CNC tool carts to organize and transport specialized tools used in the production process.

♦ Research and Development: CNC tool carts in research and development laboratories can store and transport delicate or specialized instruments and tools used in experimental setups or prototype development.

♦ Educational Institutions: Technical and vocational schools, as well as training centers, use these carts to teach students about tool organization, maintenance, and proper tool handling techniques.

MORE INFORMATION

Overall, Rousseau CNC tool carts are versatile equipment that helps enhance organization, efficiency, and productivity in various industrial and workshop settings. Their flexibility and customization options make them suitable for multiple applications.

Note: Always follow the manufacturer's instructions and safety guidelines when using this product. Following the manufacturer's guidelines is generally a good idea when using any product or equipment. Still, it's also essential to use your judgment and seek expert advice when necessary. Specifications are subject to change without notice.