Thermoformed Pallets | Vacuum Formed Plastic Pallets

If you believe cardboard or wood pallets are sufficient for safely and efficiently packaging and transporting your product, it’s time to consider the advantages of Vacuum Formed Plastic Industrial Packaging. Thermoplastic packaging is not only reusable and returnable, but also lighter, germ-resistant, waterproof, stackable, rackable, and nestable, allowing for more efficient storage and handling.

|

Custom Thermoformed Twin Sheet Plastic Pallet Key Features:

This pallet combines strength and ease of use, designed to meet demanding material handling needs |

|

What is thermoforming? Thermoforming is a generic term for the process of producing plastic parts from a flat sheet of plastic under temperature and pressure. In the highest expression of the technology, thermoforming offers close tolerances, tight specifications, and sharp detail. When combined with advanced finishing techniques, high-technology thermoforming results in products comparable to those formed by injection molding. |

|

What are the benefits of thermoforming? Thermoforming is efficient and very cost-effective for the production of many plastic parts depending on their size, shape, and quantity. Initial project costs are usually much lower, and lead times to tooling and production are generally much shorter than other processes. |

|

Need a reason to choose plastic pallets over conventional wood pallets or other types of pallets? Plastic pallets weigh significantly less making them easier to lift and handle safely. Because they're reusable and recyclable, plastic pallets are also more environmentally friendly. Our plastic pallets are also manufactured through plastic thermoforming to meet established Federal International Standards. For wood pallets to meet these standards, they must go through heat treatment and fumigation processes - costly steps which plastic pallets eliminate. |

|

Plastic pallets are designed through plastic thermoforming for durability, making them a much more cost effective choice than wood pallets which often fall apart in mere months. When you consider the years of service your plastic pallets will provide, the savings can really add up. Thermoformed Pallets Feature: Mirror Image: This plastic pallet can be used both as a base pallet and a top cap for sleeve packs or tray packs. When used as a top cap, the legs interlock with the pallet beneath. Standard Nine Legs: A standard base plastic pallet with nine legs for increased stability and strength. Twin Sheet: Two sheets of heated plastic are vacuumed formed into their respective molds, then pressed together, forming a sturdy bond along the perimeter and select points of the pallet. This process allows materials of different composition, thick nesses, and color to be fused, creating a sturdier, more attractivepallet. Reinforced: To provide extra load strength, aluminum bars are formed directly into the pallet. |

| How do we make your thermoformed product? A team of engineers is dedicated to taking your project from conceptual design through first part approval, tool machining, prototyping, and production run start-to-finish. | ||

|

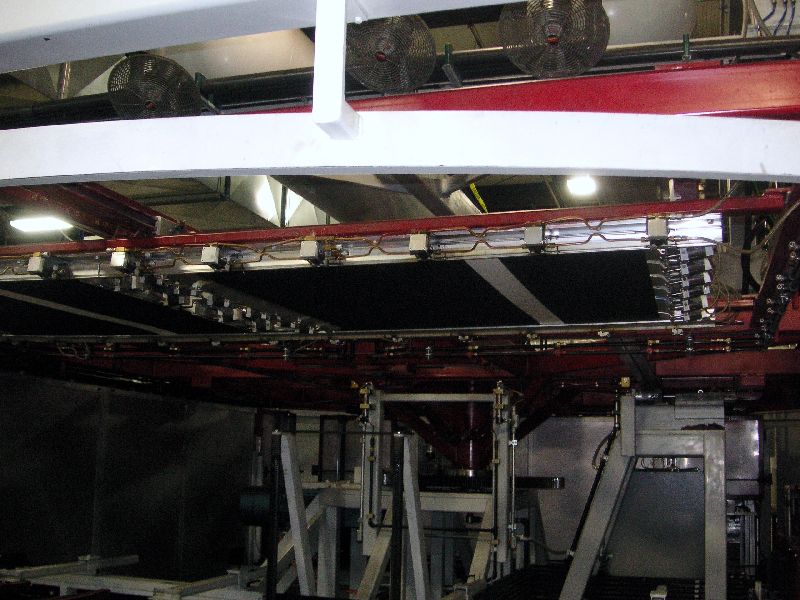

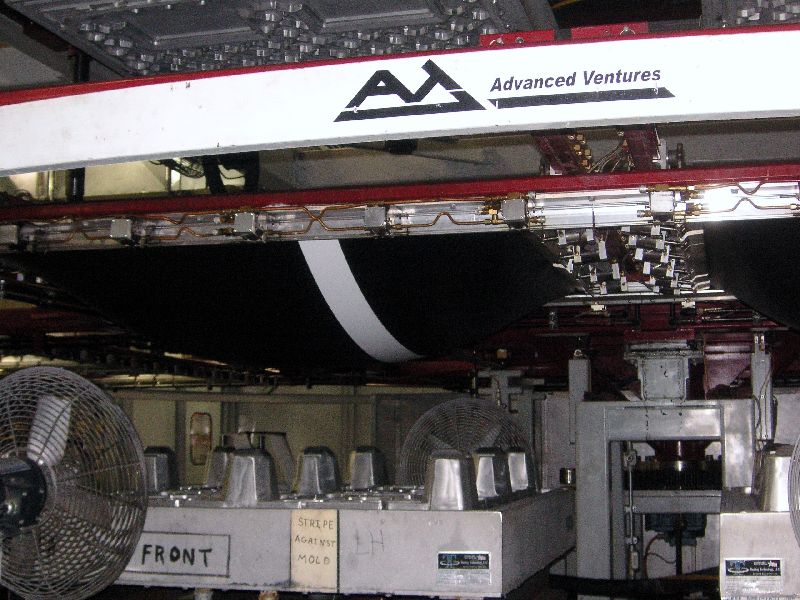

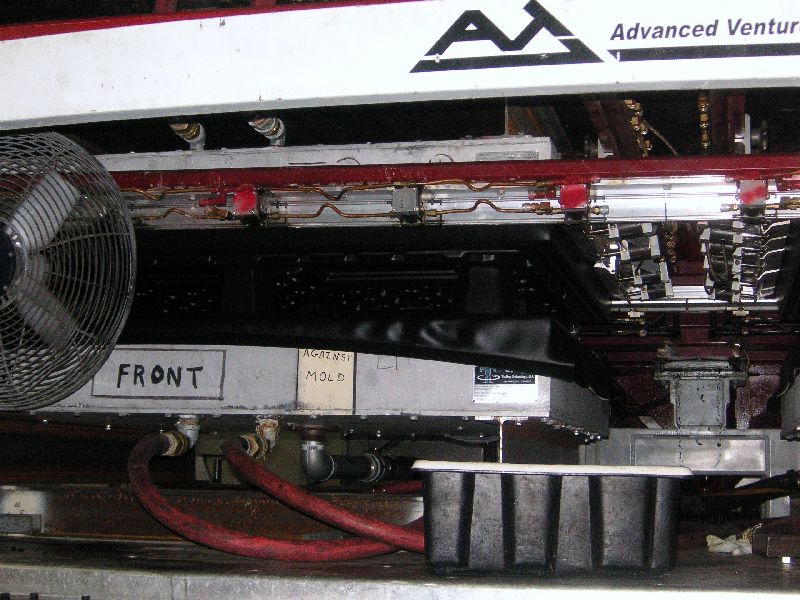

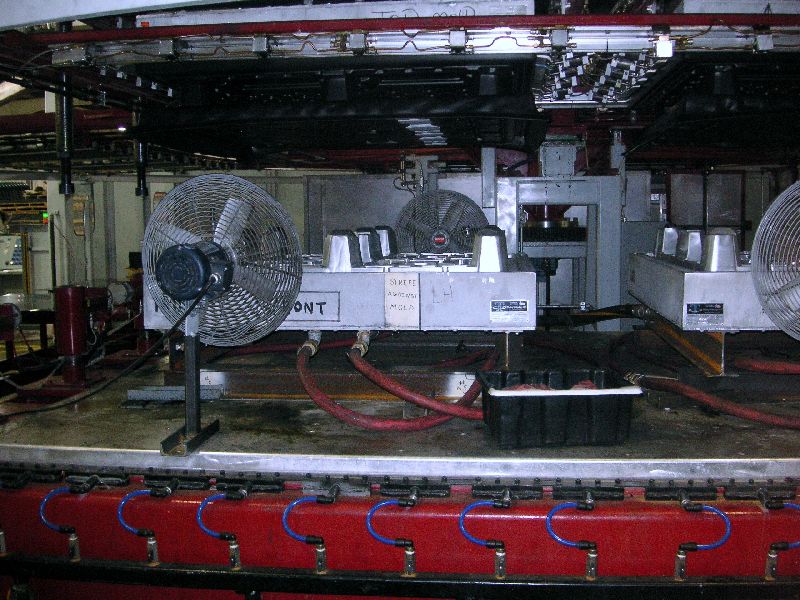

Pallet sheet is put into machine frame |

Plastic is heated before forming |

Pallet is formed under pressure |

|

Pallet is released from Mold |

Optional steel insert is formed |

Steel frame is riveted to pallet |

| Why Choose Custom Equipment Company? See examples of finished product | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

CONTACT US FOR MORE INFORMATION, 866-333-0728

OR

[email protected]